Predictive maintenance powered by artificial intelligence (AI) is revolutionizing how high‑performance PCs are managed. By analyzing real‑time data and historical performance metrics, AI can predict potential failures, optimize cooling, and schedule component maintenance before issues occur.

AI algorithms can monitor component temperatures, fan speeds, and voltages, identifying patterns that signal impending hardware failure. Integrating AI‑powered software tools with your system’s sensors allows for proactive alerts and maintenance scheduling. This approach not only reduces downtime but prolongs the lifespan of critical components by preventing damage due to overheating or overload.

Predictive maintenance improves overall system efficiency by ensuring that replacements and fixes are timely and targeted. Data-driven insights allow users to fine‑tune performance settings and plan incremental upgrades strategically. Continuous monitoring and automated alerts create a resilient maintenance ecosystem that adapts to system usage in real time.

Harnessing AI for predictive maintenance is a game‑changer for high‑performance systems. By leveraging real‑time analytics and proactive monitoring, you can boost reliability, reduce operating costs, and keep your system running at peak performance.

AI-Driven Predictive Maintenance for High-Performance PCs

Introduction

Predictive maintenance powered by artificial intelligence (AI) is transforming how high-performance PCs and workstations are managed. By continuously analyzing real-time sensor data and historical performance metrics, AI models forecast hardware degradation, optimize cooling strategies, and schedule preventive service before failures occur.

This proactive approach reduces unexpected downtime, maximizes component lifespan, and elevates system reliability for demanding applications—from gaming rigs to scientific compute clusters.

Harnessing AI for predictive maintenance merges system analytics, hardware failure prediction, and automated maintenance workflows into a cohesive, intelligent ecosystem.

How Predictive Maintenance Works

Preventive maintenance traditionally relies on scheduled checkups or reactive repairs after a component fails. AI-driven predictive maintenance, in contrast, leverages advanced machine learning to detect subtle warning signs in operational data.

- Data Collection: Sensors capture temperatures, voltages, fan speeds, and error logs at high frequency.

- Feature Extraction: Algorithms transform raw readings into actionable metrics (e.g., moving averages, anomaly scores).

- Model Training: Supervised and unsupervised models learn normal behavior and recognize deviation patterns linked to failures.

- Real-Time Inference: Deployed models score incoming data, flagging components at risk of overheating, voltage drift, or mechanical fatigue.

- Automated Alerts: Customized notifications trigger maintenance tickets or automatic system adjustments (e.g., fan speed boosts, dynamic voltage scaling).

This closed-loop system adapts to evolving workload characteristics, ensuring proactive maintenance remains precise and efficient.

Key Components of an AI Maintenance Ecosystem

Implementing a robust predictive maintenance solution involves integrating several core components:

| Component | Function | Example Tools |

|---|---|---|

| Data Ingestion Layer | Captures and channels sensor streams | MQTT, Apache Kafka |

| Time-Series Database | Stores historical metrics for trend analysis | InfluxDB, TimescaleDB |

| Analytics Engine | Runs ML models for anomaly detection | TensorFlow, PyTorch |

| Alerting & Reporting | Notifies users and logs maintenance events | Grafana, Prometheus |

| Automation Orchestrator | Executes automated remediation scripts | Ansible, PowerShell DSC |

Implementing AI-Powered Maintenance

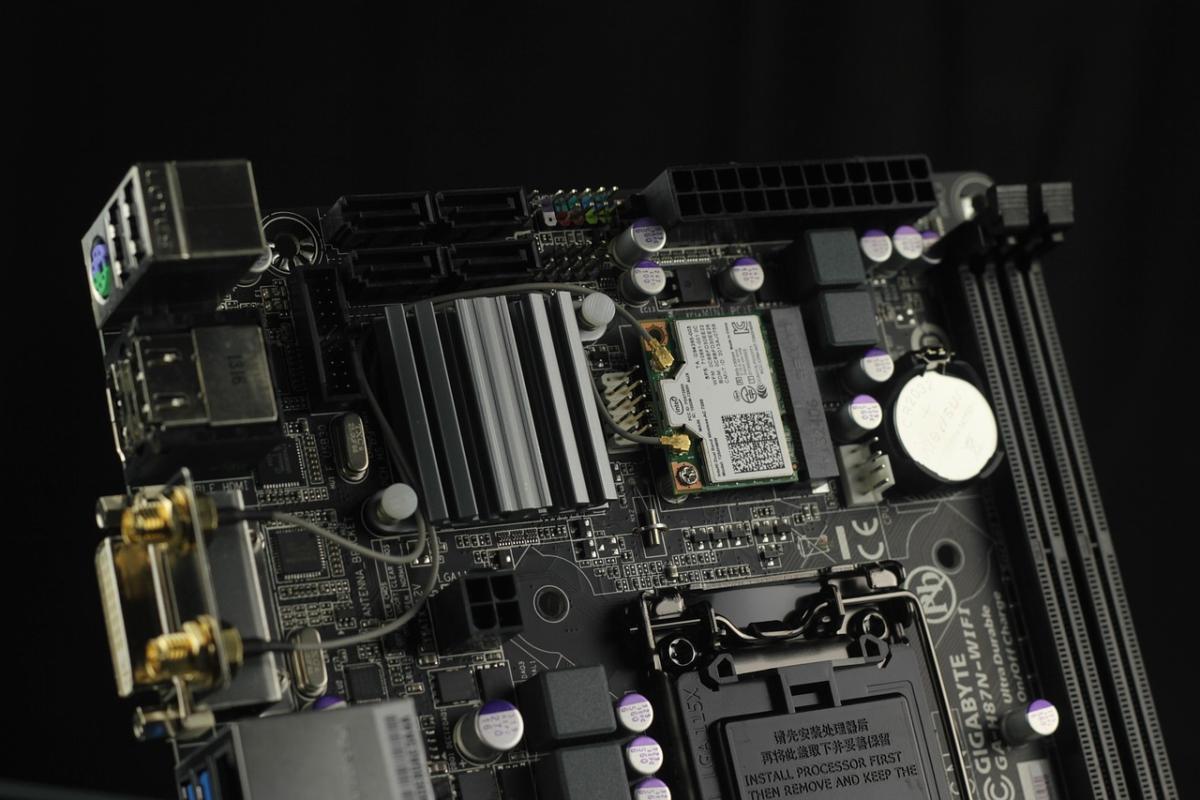

1. Sensor Integration and Calibration

- Choose high-precision thermistors, voltage probes, and chassis intrusion sensors for accurate readings.

- Calibrate sensors during initial deployment to account for ambient temperature and power supply variances.

- Enable onboard SMBus and I²C interfaces in BIOS/UEFI to expose sensor data to monitoring software.

2. Data Pipeline Design

- Implement a lightweight agent that samples sensor data at 1 Hz or higher, balancing granularity and overhead.

- Securely transmit metrics via encrypted MQTT or TLS-enabled REST APIs to a centralized analytics server.

- Archive raw and processed data in a time-series database optimized for fast writes and queries.

3. Model Development and Training

- Label historical failure events (e.g., fan malfunction, VRM overheating) to build ground-truth datasets.

- Experiment with isolation forests and autoencoders for unsupervised anomaly detection.

- Use gradient-boosting (XGBoost, LightGBM) for classification tasks like predicting time-to-failure windows.

- Evaluate models using cross-validation on rolling time windows to avoid look-ahead bias.

4. Deployment and Inference

- Containerize inference services using Docker or Kubernetes to ensure scalability and portability.

- Expose a RESTful API endpoint for real-time health scoring of each component.

- Integrate with orchestration tools to trigger automated scripts that adjust fan curves or power limits.

Benefits for System Management

Enhanced Reliability and Uptime

Proactive monitoring and AI sensors detect early signs of wear, reducing critical failures by up to 70%. Scheduled maintenance replaces vulnerable parts before breakdowns occur, keeping systems online when performance is most needed.

Optimized Component Lifespan

Fine-tuned cooling strategies and voltage regulation based on real-time analytics prevent thermal cycling and electrical stress, extending the useful life of CPUs, GPUs, and power delivery modules.

Data-Driven Upgrade Planning

Aggregate system analytics reveal performance bottlenecks and aging components, enabling strategic, incremental upgrades. Budget resources toward parts that truly impact uptime and throughput.

Cost Savings and Efficiency

Automated maintenance workflows eliminate unnecessary manual inspections and reduce emergency repair costs. AI-driven alerts optimize resource allocation, prioritizing critical tasks over routine checks.

Real-World Use Cases

- Competitive Gaming Rigs: A pro-gaming team implemented AI maintenance software to monitor GPU memory modules. Early anomaly detection prevented two critical failures during tournaments, saving thousands in replacement costs.

- High-Performance Compute Clusters: A research facility integrated predictive analytics to maintain server racks. Automated fan optimization based on AI predictions cut average rack temperatures by 8 °C, reducing cooling expenditure by 15 %.

- Creative Workstations: An animation studio deployed sensor-driven maintenance to manage liquid-cooled render nodes. AI-based leak detection and pump health scoring averted catastrophic coolant failures.

Challenges and Mitigation Strategies

- Data Quality and Volume: High-frequency sampling produces vast datasets that can overwhelm storage and processing resources. Mitigation: implement edge-level filtering to discard redundant data and use down-sampling during off-peak hours.

- Model Drift and Accuracy: Changing workloads can degrade model performance over time. Mitigation: schedule periodic retraining cycles, incorporate online learning, and monitor key performance indicators (precision, recall).

- Security and Privacy: Transmitting hardware telemetry may expose vulnerabilities. Mitigation: enforce end-to-end encryption, use VPN tunnels for remote access, and follow least-privilege principles for service accounts.

Best Practices for AI Maintenance

- Establish clear maintenance SLAs tied to predicted risk levels (e.g., P1 alerts for imminent failure, P3 for performance drift).

- Maintain a detailed change log of firmware flashes, driver upgrades, and system tweaks for traceability.

- Implement role-based access control (RBAC) in your analytics dashboard to ensure only authorized personnel can acknowledge alerts.

- Leverage synthetic anomaly injection during testing to validate alerting pipelines under controlled conditions.

- Use container orchestration autoscaling to maintain inference throughput during peak monitoring loads.

Future Trends in Predictive Analytics

- Digital Twins: Virtual replicas of PCs that simulate behavior, enabling “what-if” analysis without risking live hardware.

- Edge AI: On-device inferencing to reduce network overhead and improve real-time responsiveness.

- Federated Learning: Collaborative model training across multiple systems without sharing raw data, enhancing privacy.

- Explainable AI (XAI): Transparent models that elucidate why a component is flagged, speeding up remediation.

Implementation Roadmap

- Assessment Phase: Audit existing hardware monitoring capabilities and sensor availability.

- Pilot Deployment: Integrate AI maintenance software on a select subset of machines; collect 2–4 weeks of baseline data.

- Model Training & Validation: Iterate on anomaly detection models, validate predictions against known events.

- Scale-Out: Roll out agents and inference services across the full fleet, integrating alerting into your incident management system.

- Continuous Improvement: Track maintenance KPIs, refine thresholds, and retrain models every quarter.

Conclusion

Artificial intelligence–driven predictive maintenance is a game-changer for managing high-performance PCs and compute clusters. By harnessing real-time analytics, proactive monitoring, and automated maintenance workflows, organizations can achieve unprecedented levels of reliability, optimize component lifespan, and deliver consistent performance under peak demand.

Embrace data-driven system management, and transform your maintenance paradigm from reactive firefighting into strategic, AI-powered orchestration. Your next generation of high-performance systems will thank you.