Thermoelectric coolers (TECs), also known as Peltier coolers, offer an innovative approach to managing heat in high‑performance PCs. By utilizing the Peltier effect, these coolers provide precise thermal control and help maintain lower temperatures even under intense workloads.

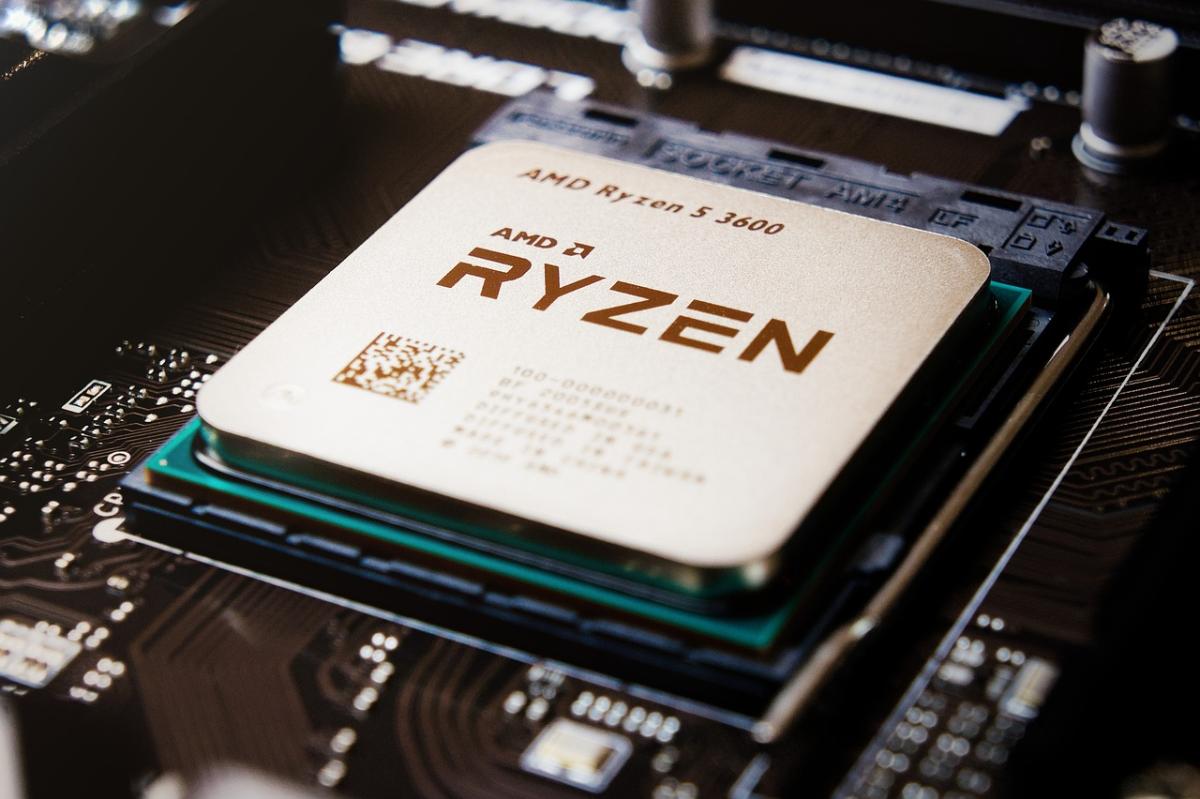

TECs pump heat from one side of the device to the other when an electric current is applied. This allows them to rapidly lower temperatures on critical components like CPUs and GPUs. Although TECs require careful integration due to their electrical conductivity and power consumption, their ability to achieve below‑ambient cooling makes them a compelling option for extreme overclocking.

When implementing TECs, ensure that proper condensation management and insulation are in place. Pair TECs with efficient heat sinks and liquid cooling loops to optimize performance. Monitor system temperatures closely to adjust the power supplied to the TEC, balancing cooling efficiency with system stability.

Thermoelectric coolers represent a cutting‑edge solution for achieving extreme thermal performance in high‑performance PCs. With careful integration and diligent monitoring, TECs can help you push the limits of overclocking while maintaining a stable, cool system.

Extreme Thermal Control with Thermoelectric (Peltier) Coolers

Unlock ultra-low temperatures and push your CPU and GPU to new heights with thermoelectric coolers—ideal for extreme overclocking and precision thermal management.

Introduction

Thermoelectric coolers (TECs), also known as Peltier coolers, offer an innovative approach to managing heat in high-performance PCs. By exploiting the Peltier effect, these devices can pump heat away from critical components, maintaining temperatures below ambient even under intense workloads. When properly integrated, TECs enable enthusiasts and professionals to achieve unmatched overclocks and stable performance.

How Thermoelectric Coolers Work

At the core of every TEC is a series of semiconductor junctions that move heat when an electric current passes through them. One side becomes cold as heat is absorbed, while the opposite side heats up as heat is expelled. Key aspects:

- Peltier Effect: Direct heat transfer between junctions under DC current.

- Bidirectional Operation: Reverse polarity flips hot and cold sides.

- Rapid Response: Instant temperature change on activation.

Learn more about our selection of high-performance TEC modules.

Benefits of TEC Cooling in High-Performance PCs

- Below-Ambient Cooling: Achieve temperatures 20–30 °C below room temperature.

- Precision Control: Fine-tune power input to regulate cold-side temperature.

- Extreme Overclocking: Stable CPU/GPU clocks at voltages that would overheat under air or liquid alone.

- Compact Form Factor: Small TEC plates integrate easily with custom loops.

Best Practices & Integration Tips

- Condensation Management: Use waterproof insulation (EPDM foam or neoprene) around the cold plate to prevent moisture build-up.

- Heat Sink Pairing: Attach the hot side to a high-performance heat sink or radiator.

- Liquid Cooling Loop: Combine TECs with a custom liquid cooling loop to dissipate heat efficiently.

- Power Supply & Control: Provide a dedicated, adjustable voltage rail (12–16 V) and use a PID controller or digital fan controller for dynamic power tuning.

- Thermal Interface: Apply premium thermal paste between the TEC and component to minimize thermal resistance.

Optimizing Heat Dissipation

Since TECs transfer an equal amount of heat plus the electrical input to the hot side, efficient heat rejection is crucial:

- High-Flow Radiators: At least 360 mm radiator capacity for multi-TEC setups.

- High-RPM Fans: Adjustable speed fans (2,000+ RPM) to maintain low liquid temperatures.

- Redundant Loop Design: Dual-loop configurations isolate TEC heat from CPU/GPU heat for balanced cooling.

Monitoring & Control Systems

Real-time monitoring and control prevent thermal runaway and ensure stability:

- Temperature Sensors: Place digital probes on both cold and hot sides of each TEC.

- PID Controllers: Automate current delivery to maintain target temperatures.

- Software Dashboards: Use applications like HWMonitor or AIDA64 to log temperatures, voltages, and wattage.

Pros & Cons of TEC Integration

| Advantage | Consideration |

|---|---|

| Below-ambient cooling for extreme overclocks | High power draw (50–200 W per TEC) |

| Instant temperature response | Requires rigorous condensation management |

| Compact integration with liquid loops | Complexity in insulation and mounting |

| Precise temperature control via PID | Additional cost for controllers and sensors |

Real-World Applications & Case Studies

Enthusiasts have used TECs to:

- Run Intel Core i9 CPUs at 5.5 GHz stable under full load.

- Maintain GPU boost clocks above 2.5 GHz on NVIDIA RTX cards.

- Explore liquid nitrogen–like performance without cryogenics.

Discover user-case builds in our article central for inspiration and detailed walkthroughs.

Future Trends & Innovations

Emerging developments in thermoelectric technology include:

- Higher COP Materials: New semiconductor compounds improving coefficient of performance.

- Monolithic Integrations: On-die TEC layers built into future CPUs and GPUs.

- AI-Driven Control: Machine-learning algorithms optimizing power input dynamically.

Conclusion

Thermoelectric coolers represent a cutting-edge solution for extreme thermal performance in high-performance PCs. By carefully managing condensation, pairing with robust heat sinks and liquid loops, and employing precise monitoring and control, you can harness below-ambient cooling to unlock unprecedented overclocking headroom. Explore our full range of TECs, liquid cooling components, and premium thermal interfaces to build the ultimate temperature-tamed rig today.