A custom water cooling loop offers superior thermal performance and aesthetic appeal for high‑performance PCs. However, maintaining an efficient loop is essential to ensure optimal cooling and longevity of components.

Establish a regular cleaning schedule to flush the coolant and remove sediment buildup. Monitor pump performance and check for leaks or tubing wear periodically. Replace coolant based on manufacturer recommendations, and ensure that water blocks, radiators, and fittings are kept free from dust. Document each maintenance cycle and update your cooling solution’s firmware if available to ensure maximum efficiency.

By following a disciplined maintenance schedule and employing best practices, you can preserve the performance of your custom water cooling loop, extend the lifespan of your components, and keep your system running at peak thermal performance.

Ultimate Guide to Custom Water Cooling Maintenance for High-Performance PCs

Master essential water cooling maintenance techniques to preserve thermal performance, extend component life, and keep your custom loop looking pristine.

Introduction

Custom liquid cooling loops deliver unmatched thermal management and stunning visual appeal for high-performance PCs. Yet even the best setups require disciplined cooling system upkeep to maintain peak efficiency, prevent corrosion, and avoid unexpected failures. This guide details comprehensive water cooling maintenance strategies—covering loop cleaning, coolant replacement, pump performance checks, and more.

Why Maintenance Matters

- Preserve Cooling Efficiency: Sediment and algae reduce heat transfer over time.

- Prevent Component Damage: Contaminated coolant can corrode water blocks and radiators.

- Ensure Reliability: Early leak and wear detection avoids downtime.

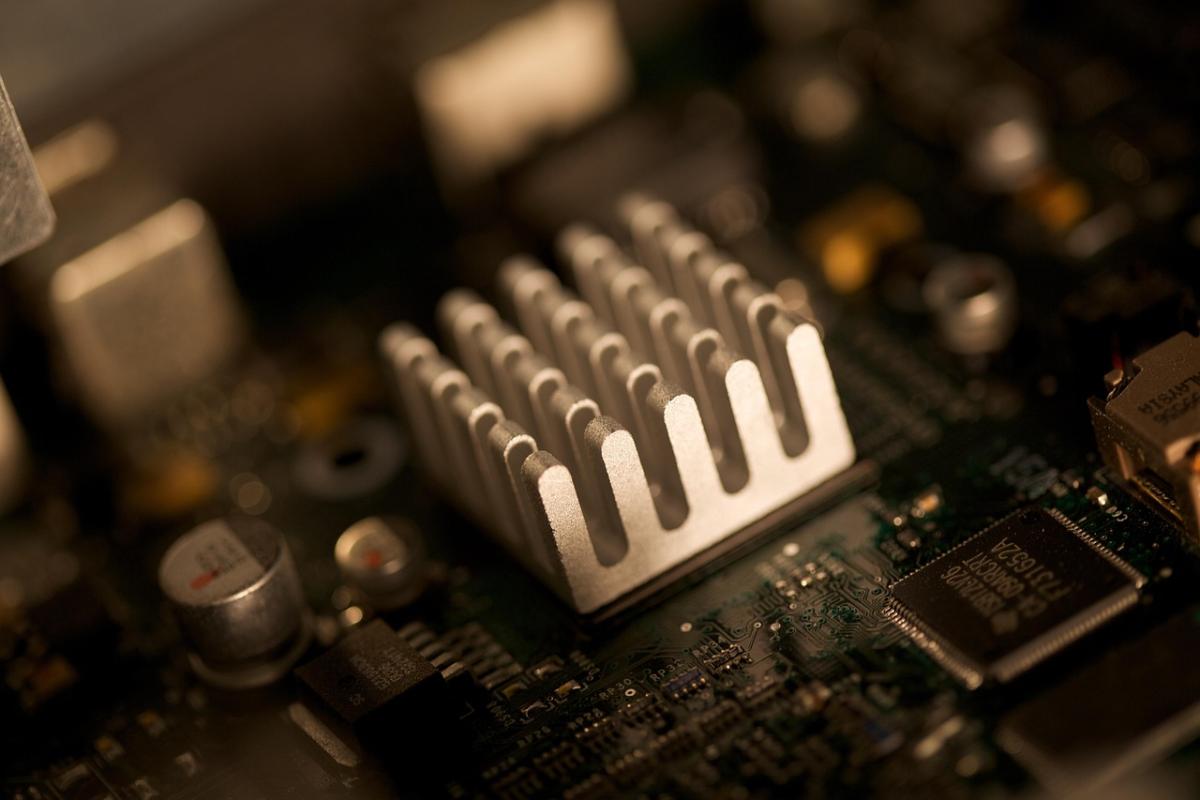

Core Components of Your Custom Loop

- Water Blocks: CPU and GPU blocks transfer heat to the coolant.

- Radiators: Dissipate heat into the ambient air with fans.

- Pumps & Reservoirs: Circulate fluid; monitor flow rate.

- Tubing & Fittings: Connect components; must be leak-proof and flexible.

Maintenance Strategies

1. Loop Cleaning & Flushing

- Power down and drain the loop into a clean container.

- Fill with distilled water and a mild cleaning solution (e.g., vinegar or specialty flush).

- Run the pump for 10–15 minutes, then drain and rinse until clear.

- Frequency: Every 6–12 months, or sooner with colored coolants.

2. Coolant Replacement

- Use manufacturer-approved coolants with corrosion inhibitors.

- Replace coolant every 12 months to maintain optimal thermal performance.

- Add biocides or UV-reactive dyes only if compatible with your loop materials.

3. Pump Performance Monitoring

- Check flow rate and noise levels monthly; a drop might signal blockage or bearing wear.

- Install a flow meter or use digital pump/reservoir combos with built-in sensors.

4. Water Block & Radiator Care

- Disassemble blocks and radiators bi-annually for thorough cleaning with a soft brush.

- Blow out dust from radiator fins with compressed air on low setting.

5. Leak Detection & Tubing Inspection

- Visual check all fittings and tubing for cracks or bulges.

- Perform a 24-hour leak test with the loop powered off but pump running.

Advanced Maintenance Tips

Elevate your routine with these professional practices:

- Use Corrosion Inhibitors: Protect mixed-metal loops.

- Implement Temperature Sensors: Monitor coolant temperature to catch thermal spikes.

- Update Firmware: For digital pump or RGB controllers, keep firmware current for stability improvements.

- Maintain a Log: Record each maintenance cycle date, coolant type, and observed temperatures.

Recommended Maintenance Products

| Product | Purpose | Key Features |

|---|---|---|

| Distilled Water & Flush Kit | Loop cleaning | Non-abrasive, residue-free |

| Biocide & Anti-Corrosion Additive | Prevent algae & corrosion | Compatible with all metals |

| High-Flow Pump | Maintain optimal flow | Digital readout, low noise |

| Compressed Air Canister | Radiator dust removal | Adjustable pressure nozzle |

| Replacement Tubing & O-Rings | Leak prevention | Flexible, high-quality rubber |

Cost vs. Benefit: DIY vs. Pre-Built Kits

- DIY Maintenance Kits: Lower cost, full control over components.

- Pre-Built Service Plans: Professional cleaning services, extended warranties.

- Balance budget with desired level of convenience and performance reassurance.

Conclusion

Consistent water cooling maintenance and disciplined cooling loop cleaning extend component life, preserve peak performance, and uphold the beauty of your custom liquid cooling setup. By flushing regularly, replacing coolant, monitoring pump performance, and inspecting all fittings, you’ll ensure your system delivers reliable thermal management for years to come.